Full project name:

Martensitic transformation in Ti alloys with high oxygen content

Project Details

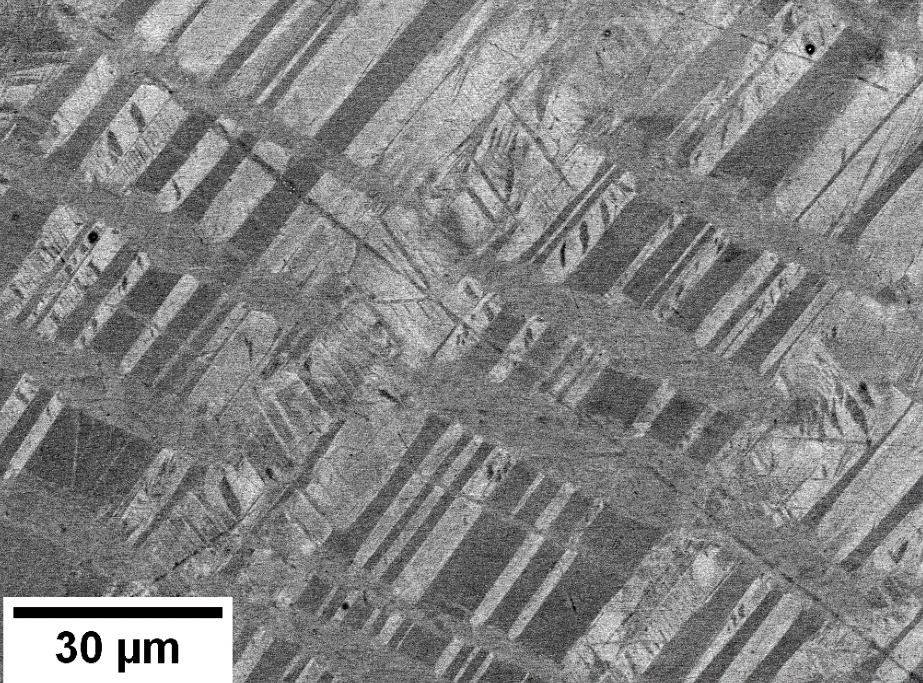

Metastable β-Ti alloys containing Zr can be substantially strengthened by interstitial oxygen content higher than 0.4 wt% without embrittlement. Oxygen is pinning the dislocations and increased stress is needed for their movement. Metastable β alloys with optimized composition can undergo stress-induced martensitic transformation to α“ phase, which can lead to ductility enhancement (TRIP effect). Simultaneously, ductility can be improved by twinning (TWIP effect). The aim of the project is to design β-Ti alloy which will be strengthened via high oxygen content (0.5 – 1 wt%) and simultaneously its β-stabilization will be optimized so that TRIP / TWIP effect is active at higher stress than in current Ti alloys exhibiting TRIP / TWIP effect (max. 600 MPa). In the studied Ti-Nb-Zr-O system, Nb and O content will be optimized first, to achieve TRIP / TWIP effect. Zr content will be optimized subsequently to get optimal strength-ductility balance via Zr-O interaction. A complementary part of the project is devoted to partial replacement of Nb by cheaper iron for improvement of final price of the alloy. The alloys will be first prepared by FAST method to explore variety of different compositions. Selected alloys will be cast by arc-melting and thoroughly studied. Active deformation mechanisms will be studied in a single-crystal of a selected alloy. The resulting alloy with high toughness could find its use in medicine (implant production) and automotive (deformation safety zones).

-

Principal Investigator

RNDr. Dalibor Preisler -

Team

3 students -

Duration

2020-2022 -

Research area

Martensitic transformations in Ti alloys

RNDr. Dalibor Preisler

Principle investigator

Current position: Ph.D. student at the Department of Physics of Materials

Main field: Titanium alloys and high-entropy alloys

Fields of interest and expertise:

- Metastable beta titanium alloys – microstructure, mechanical properties and phase transformations.

- Thermomechanical treatment of Ti alloys for application in body implants.

- Refractory high-entropy alloys with transformation-induced plasticity.

- Development of new biocompatible Ti alloys for improved combination of mechanical properties.

- Design of Zr alloys for nuclear applications.

Role of MGML in the Project

MGML instruments will be employed for arc melting of Ti alloys in laboratory amount, their characterization by XRD measurements and also for the protection of samples during thermal treatment by encapsulating into quartz tubes.