Typical applications

X-ray diffraction on polycrystalline powder and bulk samples, measurements of polycrystalline thin layers and epitaxial coatings, reciprocal space mapping, reflectivity measurements, wide reciprocal space maps, rocking curve and single crystal measurements. Preferred orientation of crystallites - texture and residual stress measurements. Profile analysis, determination of the size of coherently diffracting domains (crystallite size), study of the real structure of materials (crystal lattice defects). In-plane diffraction studies of thin layers.

Available methods

- x-ray diffraction measurements on polycrystalline powder and bulk samples

- diffraction studies of polycrystalline thin films and epitaxial layers

- reflectivity measurements

- reciprocal space mapping

- rocking curve measurements

- wide reciprocal space maps measurements

- preferred orientation of crystallites - texture measurements

- residual stress measurements

- in-plane diffraction

- profile analysis, size of coherently diffracting domains determination

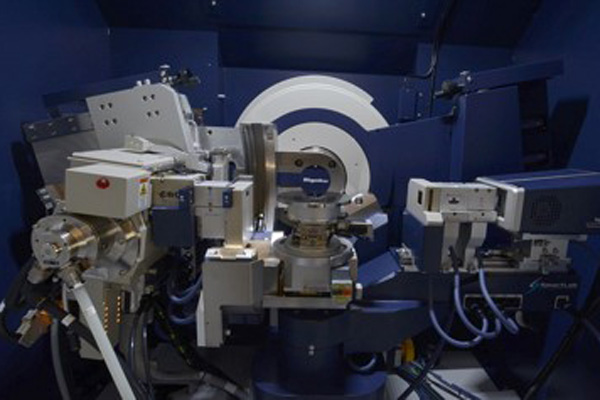

Technical specification

- Θ-Θ vertical goniometer

- 9 kW rotating anode, Cu radiation

- Bragg-Brentano geometry

- pinhole collimator (micro diffraction)

- low resolution parallel beam optics (parabolic multilayered mirror)

- high resolution setup (parabolic mirror + Ge 220 two bounce monochromator in incidence beam, channel cut analyzer in diffracted beam)

- Johansson monochromator (CuKα1 radiation)

- detectors

- 0D, 1D detectors (D/Tex U250)

- 2D detector HyPix 3000 (hybrid pixel, single photon counting technology)

- grazing incidence arm (in-plane diffraction) – measurements in coplanar and non-coplanar geometry

- Eulerian cradle

- thin film sample holder (Rx, Ry morotized rotations)

- XY-4 inch motorized sample stage

- wide reciprocal space maps measurements, parallel beam, in-plane diffraction

- high resolution measurements