Typical applications

The primary utilization of the optical furnace is for single crystal growth by floating zone method.

The whole process takes 3 days-preparation of the furnace, growth process and cleaning of the furnace; typical growth process od single crystal takes around 10 hours (depending on pulling speed and expected size). The furnace and all parameters are fully controlled via PC and remote control mode is also available.

The accessories for polycrystalline precursors preparation is available both for metallic systems by casting of the melt or sintering of oxide based powders. Maximal size of single crystal is 100 length and 10 mm diameter.

Technical specification

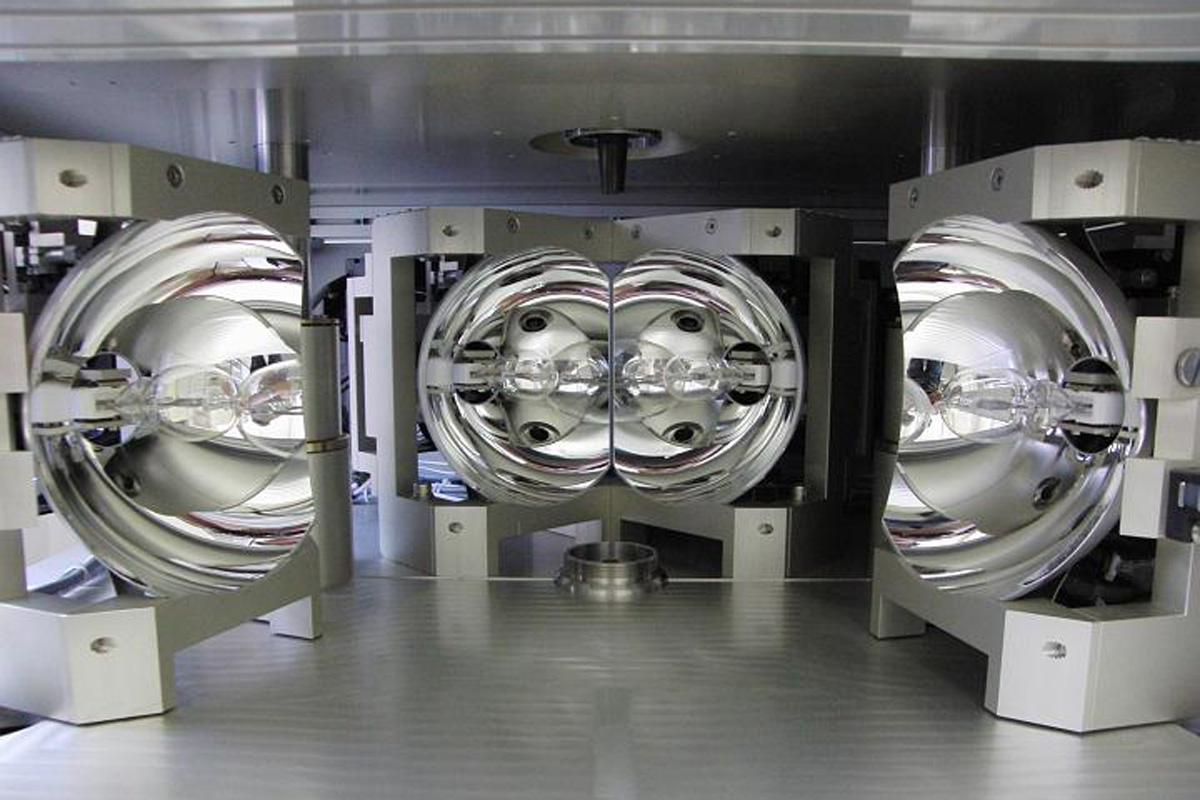

The furnace is equipped by four halogen bulbs each 1kW inside a parabolic mirrors focusing all emitted radiation to hot zone symmetrically surround the hot zone. The chamber of the furnace is made of high transparent quartz tube separating the sample space from outside space. The chamber can be evacuated (10-6 mbar) or pressurized (10 bars) by air, oxygen, Argon (6N) or Ar + 5 % H2 mixture. The gas inside the chamber can be static or with flow up to 2 l/min.

The highest available temperature is 2100 deg., which strongly dependents on color of the polycrystalline precursor.

Both upper and bottom shafts can rotate up to 100 rpm to homogenize the temperature profile of the hot zone. Pulling speed of the single crystal is within the interval 0.1-100 mm/h.